12 |

THIELE

Chain Company

|

Drop Forging

THIELE corrosion protection

As Tectyl and Corostar are not permanent coatings they do not provide suffcient protection for underground use,

especially when aggressive mine water is present. This is why THIELE has developed hot-dip galvanising (TZN)

technology for chains intended for operating conditions of this type.

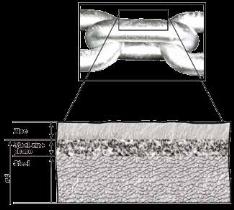

During the hot-dip galvanising process a permanent corrosion-proof coating is formed on the surface of the

chain. This coating comprises two layers: an iron-zinc intermetallic phase and a solid zinc surface coating. This

protective layer is smooth, non porous, highly adherent and therefore abrasion resistant. Even those surfaces that

are exposed during underground service are still protected from corrosive attack. The phenomenon on which this

observation is based is known as electrochemical or cathodic galvanising protection.

Long-term observations show that hot-dip galvanised chains have a greatly improved service life and chain

failures are reduced dramatically.

3. Hot-dip galvanising (TZN)

Chain size

d x t [mm]

Article No.

Round Link

Chain

Article No.

Flat Type

Chain

Article No.

DUALINK-

Chain

14 x 50

F13195

--

--

18 x 64

F13212

--

--

19 x 64,5

F13350

--

--

22 x 86

F13402

--

--

24 x 86

F13483

--

--

26 x 92

F13499

F14971

--

30 x 108

F13657

F13773

--

34 x 126

F13820

F13808

--

38 x 126

--

F15052

--

38 x 137

F138972

F13893

F13917

42 x 146

--

F15040

F15015

48 x 144/160

--

F14951

--

48 x 152

--

F14957

F14954

Hot-dip galvanising is the only

effective and proven form of

corrosion protection for mining

chains.